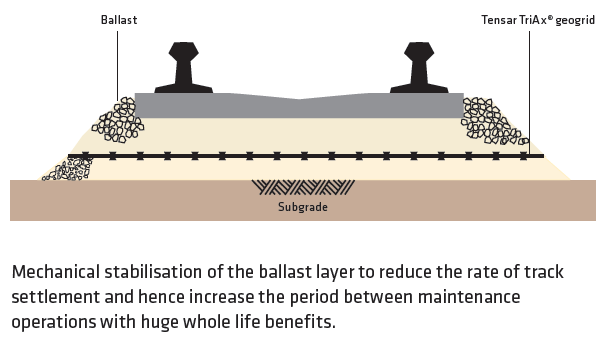

Stabilisation of the ballast layer using Tensar® TriAx® geogrids can substantially delay track settlement increasing periods between maintenance operations

2 MAJOR APPLICATION AREAS FOR THE USE OF TENSAR TRIAX® :-

Track Maintenance, involving ballast tamping or full ballast replacement, arises not only on weak subgrades but also on firmer supporting soils. Mechanical stabilisation of ballast, using Tensar geogrids, gives the railway engineer a rapid and safe solution. Tensar geogrids have been used to stabilise track ballast since the early 1980s to decrease maintenance costs and maintain ride quality. Mechanical stabilisation of the ballast layer to reduce the rate of track settlement and hence increase the period between maintenance operations with huge whole life benefits.

RESEARCH HAS DEMOSTRATED THAT TENSAR GEOGRIDS CAN:

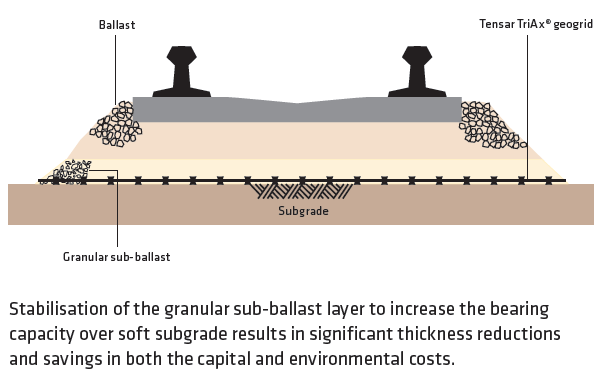

When constructing track over soft subgrade soils having a low bearing capacity, it is necessary to improve the foundation to support the ballast effectively. This can

involve a time consuming chemical stabilisation of the subgrade or deep excavation followed by importation and placement of a thick and expensive granular sub-ballast layer.

Introducing a Tensar mechanically stabilised layer using TriAx® geogrids, enables a significant reduction of sub-ballast layer thickness for the same bearing capacity.

This results in reduction of subgrade excavation and spoil disposal and much less imported sub-ballast fill, while still achieving the target stiffness value required for the support

of the ballast.

Tensar has extensive experience in mechanically stabilising sub-ballast layers, especially in the upgrading of European railway corridors, that has resulted in many successful cost-effective

installations.